Your Source for Environmental Equipment

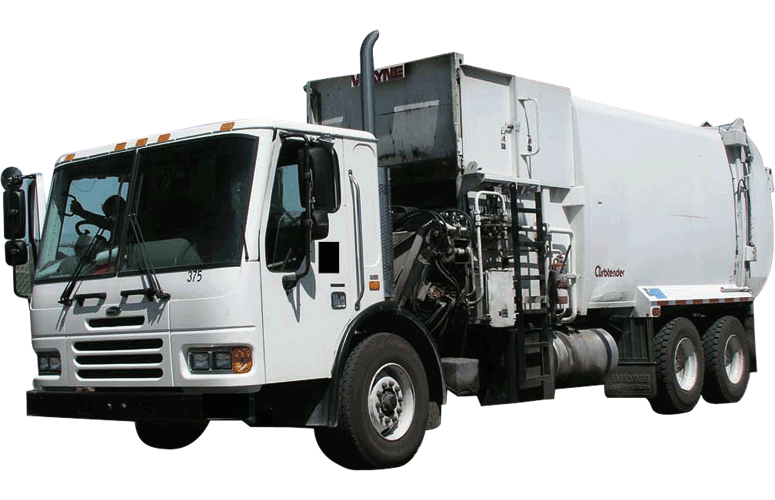

Quality Refuse Solutions is part of the Quality Truck Care Center family business in the Fox Valley offering service and sales for all makes and models of refuse equipment. We offer diagnostic repair and full refurbishment of all types of refuse equipment including but not limited to Front End Loaders, Rear End Loaders, Automated Side Loaders, and Rolloffs/Hooklifts. All modifications and refurbishing is done in house by our excellent team of fabricators. After your equipment has been brought back to our high refurbishment standards we can offer a high quality paint option to keep your equipment looking as good as it works representing your company in the best possible way. We keep a high volume of fast moving and hard to find refuse parts (Leach, Heil, McNelius, E-Z Pack, Etc.) on hand to keep your equipment on the road.

- Mounting & dismounting of refuse body

- Hydraulic hoses, pumps & pto’s

- Cylinder replacement or repacking

- Electrical wiring, troubleshooting/diagnostics, camera system installation

- Custom metal fabrication, welding, floor liners, hopper liners

- Replacement pins, bushings, bosses & bearings

- Full service/repair and preventative maintenance

- Full service ASE mechanic shop

- Body shop & Paint shop

-

Hydraulics: Tested @ operating pressure

- Remove/replace worn out and leaking hydraulic hoses

- Remove/replace worn out and leaking hydraulic tubes

- Replace/re-pack leaking hydraulic cylinders

- Repair/rebuild operating valves

- Replace all pins & bushings

- Replace worn out spool valves and detents

- Replace faulty Main Reliefs and set operating pressures

- Remove/replace faulty & worn out pumps/pto’s

-

Electrical:

- Test all components when mounted, repair as needed

- Trouble shoot/diagnose faulty wiring, switches, inop body components

- Replace faulty wiring in the body

- Replace/update body lighting with LED lights

- Replace faulty proxy/limit switches

- Address all other issues that are faulty

-

Metal Fabrication:

- Install overlay floor liners to bring back to spec. as needed

- Install overlay hopper liners to bring back to spec. as needed

- Remove/replace wear bars inside body

- Install overlay tailgate liners to bring back to spec. as needed

- Remove/replace rear load troughs

- Custom metal fabrications

Body Components:

-

ALL COMPONENTS CHECKED AGAINST OEM SPECIFICATIONS

- Replace worn out packer/carrier components

- Ejection blade wear shoes/bars

- Floor supports if rotted/worn out

- Body long members if rotted/worn out

- Mount/dismount body on all types of chassis

- Shorten/lengthen frame rails

- Shorten/lengthen wheel base

- Sand blasting

- Full body shop/paint booth using Akzo Nobel paint products

-

CUSTOMER UPGRADES:

- Remove/replace all hydraulic cylinders

- Remove/replace all hydraulic tubes

- Install floor liner

- Install hopper liner